Aerogel Granules: A Comprehensive Overview of Their Properties, Benefits, and Applications

Aerogel granules represent one of the most innovative forms of aerogel materials, combining the exceptional thermal and acoustic properties of aerogels with the practical advantages of granular forms. This unique material offers versatility in a wide range of industries, from insulation to environmental protection. In this article, we will explore the properties, benefits, and various applications of aerogel granules.

What are Aerogel Granules?

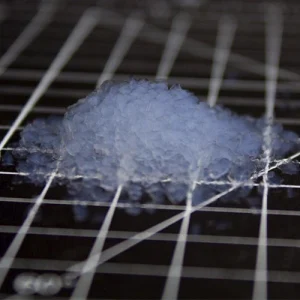

Aerogel granules are small, solid particles made from aerogel material, typically produced through a process known as sol-gel synthesis. The granules are created by breaking down larger aerogel blocks or sheets into smaller, more manageable pieces. This process results in lightweight, highly porous particles that maintain the excellent insulating properties of traditional aerogels, but offer additional flexibility in application.

The structure of aerogel granules consists of a network of silica or polymer-based material, providing a low-density, high-surface area, and highly porous texture. These granules can be manufactured in various sizes and compositions, depending on their intended use, and they retain many of the key properties that make aerogels so valuable in industrial and scientific applications.

Key Properties of Aerogel Granules

- Low Density One of the defining characteristics of aerogel granules is their extremely low density. They are among the lightest solid materials known, which makes them easy to handle and transport. The low density of aerogel granules also allows for applications in areas where weight is a critical factor, such as in aerospace or construction.

- Exceptional Thermal Insulation Aerogel granules retain the outstanding thermal insulation properties of aerogels. Due to their porous structure, they have a low thermal conductivity, which makes them highly effective at preventing heat transfer. Aerogel granules are used in thermal insulation applications where efficient heat management is essential, such as in the energy sector, cryogenics, and industrial equipment.

- High Surface Area The surface area of aerogel granules is incredibly high due to their porous, interconnected structure. This property makes aerogel granules ideal for applications requiring high adsorption capacity, such as in filtration and absorption technologies.

- Acoustic Insulation The porosity and lightweight nature of aerogel granules also make them highly effective at insulating against sound. Their ability to absorb and dampen sound waves makes them useful in noise control applications, particularly in industries where reducing noise is essential.

- Mechanical Strength Despite their low density, aerogel granules are relatively strong for their size. They exhibit a good balance between mechanical strength and lightweight properties, making them useful in applications where a combination of both is required.

- Non-Toxic and Environmentally Friendly Aerogel granules, especially those made from silica, are non-toxic and environmentally friendly. They are safe to handle and can be used in applications where safety and sustainability are important considerations.

Benefits of Aerogel Granules

- Ease of Handling and Transport The granular form of aerogels makes them easier to handle and transport compared to solid aerogel blocks or sheets. Granules can be packed, shipped, and used in a variety of forms, from loose-fill insulation to composites or packed filters, without the need for specialized equipment.

- Cost-Effectiveness While aerogels in general are known for their high cost due to their complex manufacturing process, aerogel granules provide a more cost-effective option in some applications. Their ability to be mass-produced in granular form allows for economies of scale, which can help reduce overall costs, especially in bulk applications.

- Customization Aerogel granules can be customized in terms of size, porosity, and composition to suit specific applications. This versatility allows manufacturers to tailor the properties of the granules to meet the demands of different industries, such as construction, energy, or electronics.

- Versatility in Applications The granular form of aerogels offers unique advantages in various industries, from insulation to filtration and energy storage. Their ability to be used in a wide range of applications makes them a versatile solution for many modern challenges.

Applications of Aerogel Granules

- Thermal Insulation Aerogel granules are widely used in thermal insulation applications due to their low thermal conductivity. They are particularly valuable in situations where space is limited, as they provide superior insulation in a lightweight, easily manageable form. Some key uses include:

- Building Insulation: Aerogel granules are used in wall panels, flooring, and ceilings to improve energy efficiency in both residential and commercial buildings.

- Industrial Insulation: They are used in high-temperature insulation systems for industrial applications, including boilers, furnaces, and cryogenic tanks, where efficient thermal protection is required.

- Oil Spill Remediation Due to their high surface area and ability to absorb a wide range of substances, aerogel granules are highly effective for environmental clean-up, particularly in oil spill remediation. The granules can absorb large quantities of oil and other hydrophobic substances, helping to mitigate the impact of oil spills in oceans and other bodies of water.

- Filtration Systems Aerogel granules’ high surface area and porous structure make them an excellent choice for filtration systems. They are used in air, water, and gas filtration to trap pollutants, dust, and other particles. Their ability to absorb gases and liquids makes them a valuable material for cleaning air and water in various industries, including environmental protection and HVAC systems.

- Energy Storage Aerogel granules are being explored in the field of energy storage, particularly in supercapacitors and batteries. Their high surface area and porosity make them ideal for use as electrode materials in energy storage devices, helping to improve their efficiency and energy density.

- Soundproofing and Acoustic Insulation The unique structure of aerogel granules also allows them to be used for soundproofing applications. Their ability to absorb and dissipate sound waves makes them ideal for use in noise control solutions for buildings, machinery, and transportation systems.

- Lightweight Composites Aerogel granules are also used as lightweight fillers in composite materials. These composites can be used in a variety of applications, including the aerospace industry, where lightweight yet strong materials are required for structural components.

- Thermal Management in Electronics In electronics, aerogel granules are used to manage heat dissipation in high-performance components. The granules help to prevent overheating in sensitive electronic devices, including batteries, chips, and other components.

Conclusion

Aerogel granules represent an exciting development in the world of advanced materials. Combining the outstanding properties of aerogels with the practical advantages of a granular form, they offer versatile solutions across a wide range of industries. Whether in thermal insulation, environmental protection, energy storage, or noise control, aerogel granules are proving to be an invaluable resource for tackling modern engineering challenges. As the demand for high-performance materials grows, aerogel granules will continue to play a significant role in shaping the future of many industries.